Choosing a sustainable floor finish in isolation does not ensure its reuse or recyclability at the end of its life. How the flooring has been installed has a significant effect on circularity.

Floor coverings installed using adhesives can be difficult to reuse or recycle on uplift due to contamination.

This can result in flooring sent for incineration or landfill, and significant rectification work to the sub-floor before the next installation.

IOBAC Adhesive-free Flooring Installation Tabs such as MagTabs® and Tab-It® address this by enabling floor coverings to be affixed securely throughout the life of the installation, yet cleanly and easily uplifted.

Flooring materials can be reused, or more easily recycled via the manufacturer’s take-back scheme.

And in an industry-first, Shaw Contract EMEA have gone one step further by offering a 15-year warranty for its carpet tiles when installed using MagTabs, including the re-installation of the tiles in a second location.

Plus, all IOBAC products come with our Reuse Promise, giving peace of mind that the flooring system specified today is future-proofed and can go on to have another life.

Using IOBAC Tabs extends the useful life of flooring and keeps it at its highest value.

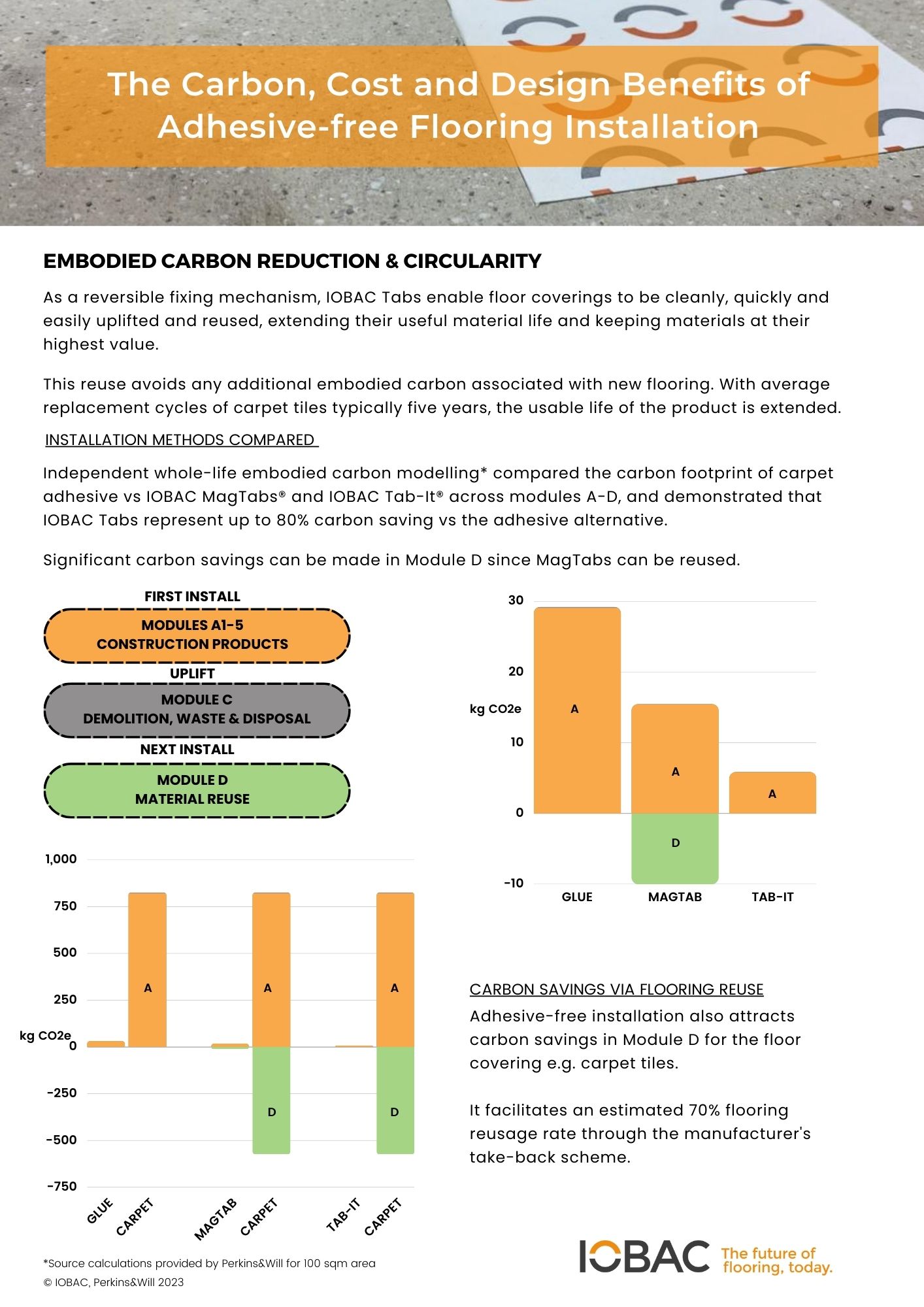

Reuse avoids any additional embodied carbon associated with new flooring.

Independent whole-life embodied carbon modelling by Perkins&Will compared the carbon footprint of carpet adhesive vs IOBAC MagTabs® and IOBAC Tab-It® across modules A-D.

It demonstrated that IOBAC Tabs represent up to 80% carbon saving vs the adhesive alternative. Significant carbon savings can be made in Module D since MagTabs can be reused.

Adhesive-free installation also attracts carbon savings in Module D for the floor covering and sub-floor as the materials are preserved for future reuse.

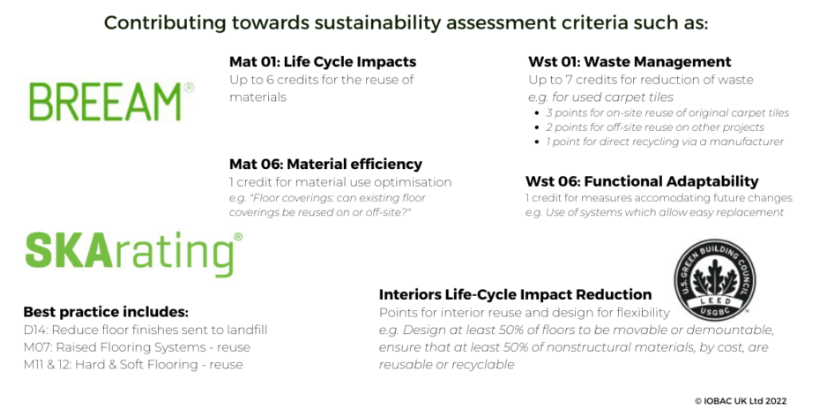

Sustainability certification schemes such as BREEAM and RICS’s SKA Rating recognise this contribution to embodied carbon saving with credits awarded for material efficiency, reuse and waste reduction.

An example of credits available within BREEAM:

Wst 01: Waste Management

Up to 7 credits for reduction of waste e.g. for used carpet tiles

- 3 points for on-site reuse of original carpet tiles

- 2 points for off-site reuse on other projects

- 1 point for direct recycling via a manufacturer

For more information on credits available, see our Better Way for Flooring Infographics.

Rectifying sub-floors contaminated with adhesive is messy, expensive and carbon intensive as shown below.

Whereas with clean, damage-free uplift, adhesive-free installation protects and preserves building assets such as metal raised access flooring, saving time, money and carbon.

Metal Access Flooring Remediation

Detackifying fluids are often used to remove old flooring adhesive.

An intensive process either requiring panels to be taken away for off-site treatment (incurring carbon costs).

Or careful programming into the on-site fit-out scheme is needed to avoid the fluid damaging other finishes such as skirting paint.

Concrete Sub-Floor Remediation

Typically done using grinding machines that generate a significant amount of dust, followed by applying a layer of cementitious screed. This method presents respiratory hazards to health to the contractor, requiring risk assessment and potential provision of PPE.

Given that concrete production contributes 8% of global annual carbon emissions, using additional cement-based products such as screed to rectify adhesive contamination is really not a sustainable approach.

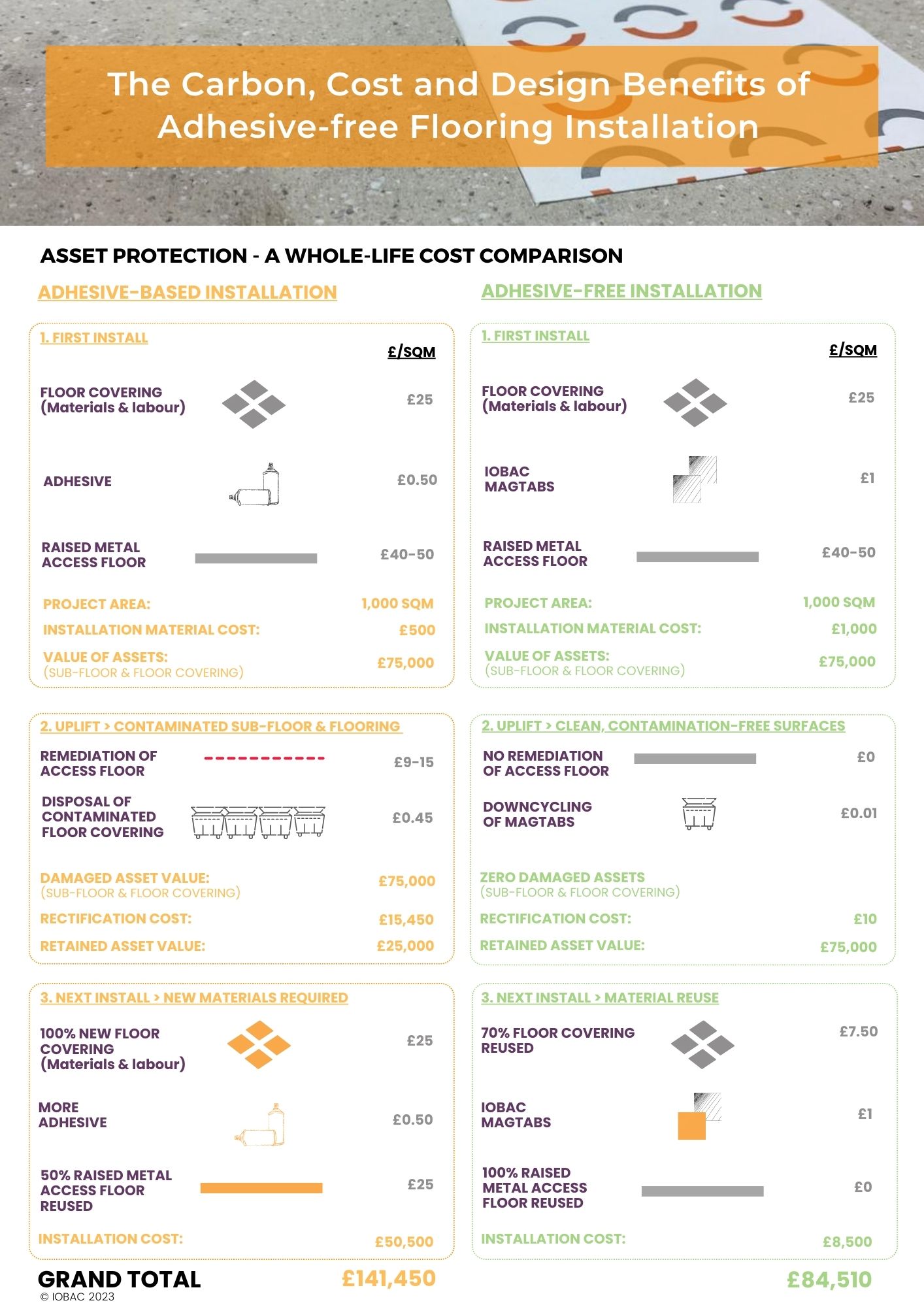

In an example 1,000m2 project, the flooring assets could be worth a total of £75,000

- Average cost of flooring – £25 per sqm

- Average cost of raised metal access flooring – £50 per sqm

These assets would be damaged by using just £500 worth of adhesive!

The cost to repair the damage, and dispose of contaminated floor covering is around £15,500.

Whereas, installation using IOBAC Adhesive-free Flooring Installation Tabs keeps the sub-floor clean and ready for immediate reuse.

That’s

ZERO damaged assets

ZERO mess

ZERO cleaning costs

ZERO dilapidation costs

Plus the floor covering can be reused or recycled, so costs for the next install are reduced due to material reuse.

And ongoing repair and maintenance costs are also significantly reduced since specialist contractors or tools are not required. As a self-maintenance solution for clients, in-house staff can simply lift and replace damaged flooring tiles themselves.

For our 1,000m2 example project, adhesive-free installation costs are 40% less than traditional methods across a whole-life cost comparison.

Download our whitepaper to see the full costings

These significant cost savings are achieved via reduced remedial costs and reuse of flooring and sub-flooring materials.

COST OF ADHESIVE- BASED INSTALL

- 1st Install £75,500

- Uplift & Remedial Work £15,450

- 2nd Install £50,500

GRAND TOTAL £141,450

COST OF ADHESIVE- FREE INSTALL

- 1st Install £76,000

- Uplift & Remedial Work £10

- 2nd Install £8,500

GRAND TOTAL £84,510

IOBAC MagTabs and Tab-It are used to install carpet tile, +4mm Luxury Vinyl Tile (LVT) and woven vinyl tiles onto all common prepared sub-floors.

They are a universal fixing system meaning adhesive-free design is not limited to a particular flooring type or brand.

For example, carpet and LVT can be seamlessly combined.

USE ON MAGNETICALLY RECEPTIVE SUB-FLOORS

> Metal raised access flooring

Tab-It

USE ON ON ALL OTHER COMMON SUB-FLOORS

> Non-metal raised access flooring

> Concrete, Wood, Ceramic

> Vinyl/lino/VCT

Designing for deconstruction means buildings can be more easily disassembled, and materials reused on other projects.

Using modular materials and reversible fixings such as IOBAC MagTabs and Tab-It enables the flooring and sub-floor to be easily separated and reused.

Flooring is no longer permanently fixed, making designs easy to deconstruct and repurpose,

which saves time, waste, money and additional carbon

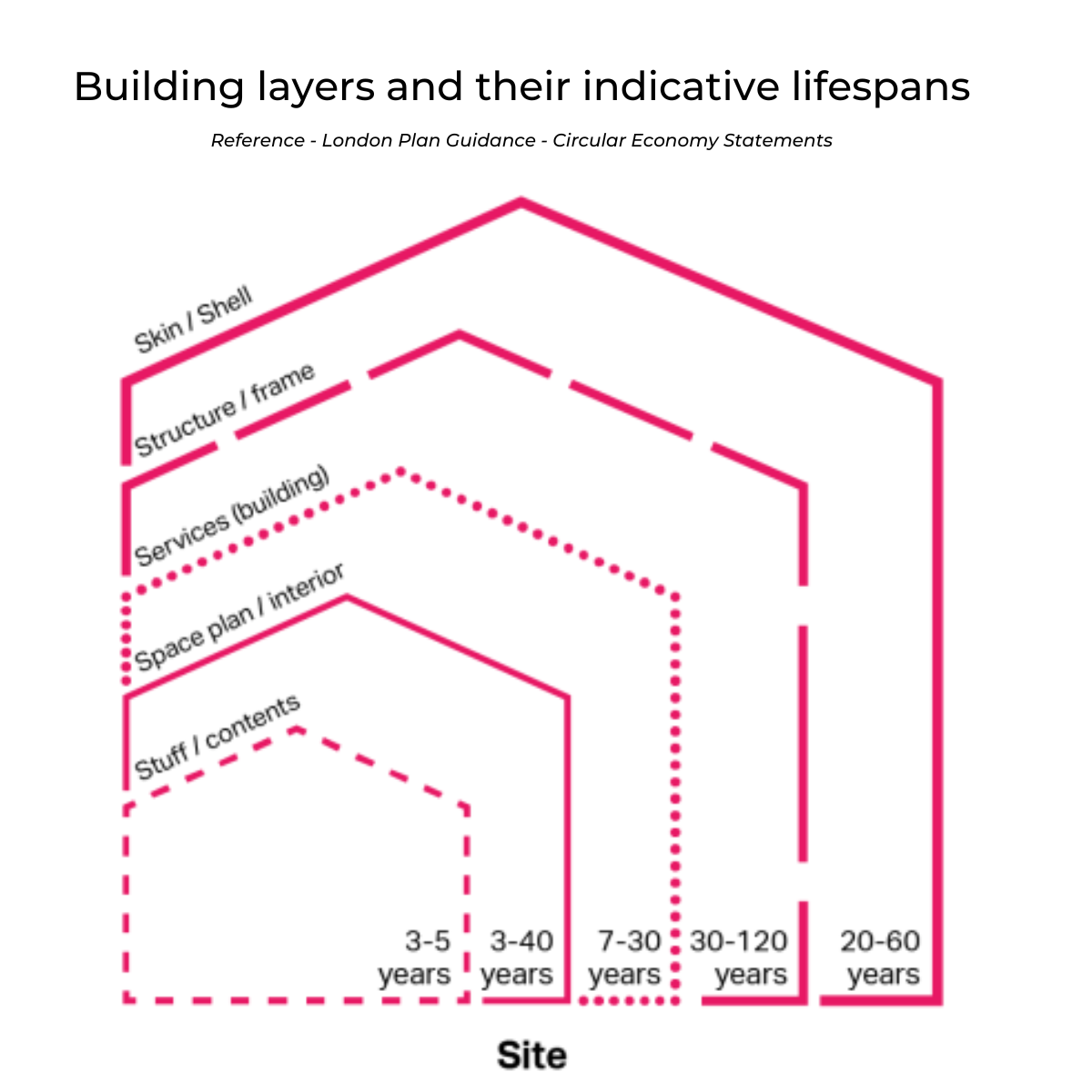

Building in layers is one of the design principles discussed in London Plan’s guidance on Circular Economy statements.

Referencing the “Shearing Layers – 6Ss” concept, it recommends that

✅”different parts of the building are accessible and can be maintained and replaced where necessary”

✅”To support reuse and recycling, the different layers should be independent, accessible and removable whilst maintaining their value, where possible. This is especially important for layers that may need more frequent replacement, such as building services and internal fit-outs.”

Permanently sticking down floor coverings to sub-floors risks damaging both layers, particularly the sub-floor which has a longer life expectancy.

Flex-Agility – Be creative with intricate designs, switch designs quickly and easily repurpose and demarcate spaces,

all whilst knowing disassembly will be easy and sustainable, and flooring materials need not be wasted.

And if accidents happen, damaged floor tiles can be easily replaced by in-house staff, no specialist contractors or tools required.