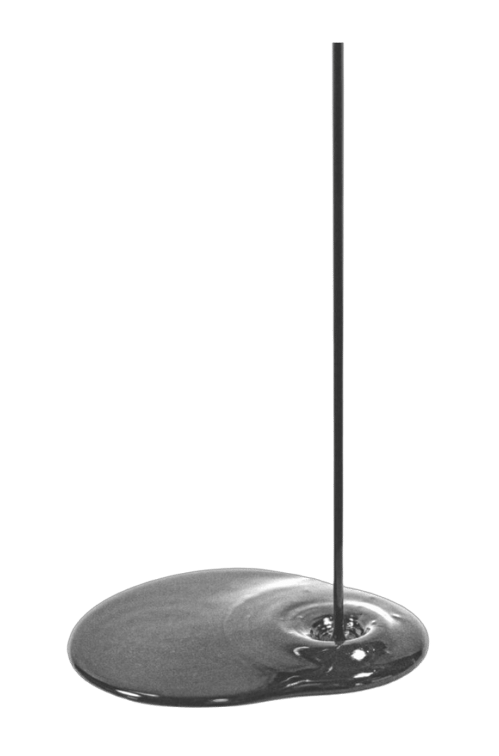

These magnetically receptive resins form a permanent, durable base onto which a wide choice of floor coverings can be fixed adhesive-free. Installed once, the resin base stays intact, enabling quick and easy repairs and design changes.

Adhesive-free flooring that’s tough enough for the harshest spaces, yet kind to the planet

Applied wet, IOBAC magnetically receptive resins fast-cure to a permanent, durable base within hours, making for super simple and quick flooring installation as shown in this video.

For use with:

- Magnetically backed Luxury Vinyl Tile or magnetic wood flooring – simply laid on top

- Standard-backed floor coverings such as Luxury Vinyl Tile (LVT), carpet and woven vinyl – installed using IOBAC MagTabs.

With a choice of two IOBAC resins, there is an option for most built environments:

Express Cure Resin

- Super fast cure of just 1-2 hours for minimal disruption to business operations

- Moisture and surface tolerant

- Ideal for commercial and refurbishment projects

Quick Cure Resin

- Dual Grip power combines dry-adhesive tack with magnetism for maximum hold between the resin base and flooring tile

- Quick cure time (approximately 4 hours)

- Ideal for high-traffic areas demanding maximum durability, as well as new-build projects

The Better Way To Install Flooring

Faster, More Cost-Effective Installations

Save Materials, Time and Money

- Installation time up to 3x quicker than traditional installation techniques

- No need to remove existing flooring – can be installed directly onto ceramic tile

- Business disruption minimised – floor can be trafficked immediately

- Can be applied to floors of up to 95% humidity without the need for moisture mitigation materials such as dampproof membranes

- Encapsulated system – dust contamination is eliminated

- Existing sound asbestos flooring can be permanently isolated, saving the time, risks and costs associated with abatement

Reusable, Circular Materials

A Sustainable Flooring Choice

- VOC-free plant-based resin containing metallic additives from recycled scrap iron

- Forms a permanent base, which can be reused time and time again

- Flooring is uplifted cleanly, for easy reuse or recycling

- No need to dig up and dispose of existing flooring, eliminating waste and dusty/hazardous removal processes

Design Flexibility

Flexible Flooring

- Zero sub-floor mess, cleaning or remedial costs on uplift

- Easily redesign and reformat flooring with minimal disruption

- Self-maintenance solution – simply lift up damaged tiles and replace

How Magnetically Receptive Resin Works

Installation of IOBAC Magnetic Flooring System in a kitchen (Video courtesy of Resincoat)

Quick and Easy Installation Steps

- Mix Resin Parts A and B together

- Mix in Part C, the metallic additive

- Trowel onto a prepared base

- Roller to remove trowel marks

- Leave to cure – Express Cure (1-2 hours), Quick Cure (approx 4 hours)

- Install top surface tiles:

- Magnetically backed Luxury Vinyl Tile or magnetic wood flooring – simply laid on top

- Standard-backed floor coverings such as Luxury Vinyl Tile (LVT), carpet and woven vinyl – installed using IOBAC MagTabs.

Product Information

Magnetic Resin can be applied directly to the following subfloors:

- Polished Concrete

- Plywood

- Vinyl, VCT or Linoleum

- Terrazzo

- Ceramic Tile

See Installation Guidelines below for detailed preparation instructions

Compatible Floor Covering Types

- Magnetically backed Luxury Vinyl Tile or magnetic wood flooring – simply laid on top

- Standard-backed floor coverings such as Luxury Vinyl Tile (LVT), carpet and woven vinyl – installed using IOBAC MagTabs.

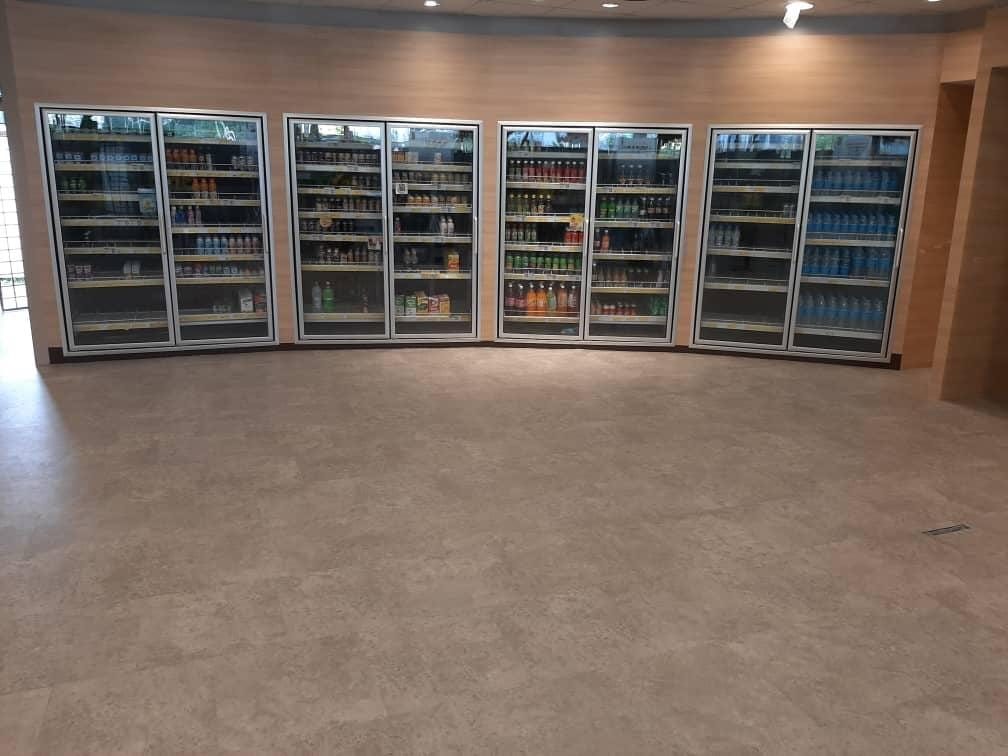

Magnetically Receptive Resin In Action

Our Customers