How did IOBAC come to be? Why was it formed?

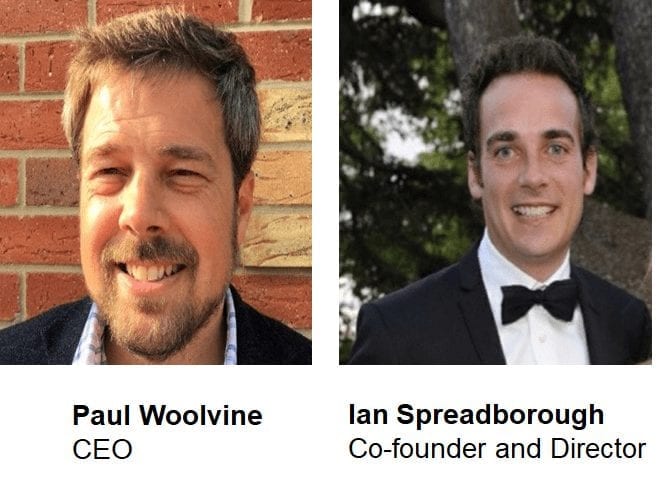

Ian Spreadborough (IS): I’ve been involved in the flooring industry in one way or another since 1994 and started working on the magnetic flooring project in 2009. Straight away I knew there was something special there. It was while pitching IOBAC’s magnetic flooring solution to 3M that I met Paul. We’ve now both been at the company since 2014 and 2016 respectively.

As for the why… well, as a company, we looked at a range of different issues that people had with their flooring and set about solving their problems. To this day, we as a company remain focused on delivering businesses with tangible positive results. In a nutshell, we thought to ourselves: ‘there has to be a better way’.

Damp, for example, and damp concrete sub floors exceeding 75 per cent relative humidity, was and continues to be the single biggest flooring issue for many people. IOBAC flooring eliminates the need for a damp-proof membrane. That’s huge, not only because it reduces damp-related issues, but also because it increases speed of install and drastically reduces any time and effort dedicated to maintenance and replacement. We make flooring more simple and easier.

Paul Woolvine (PW): IOBAC was born out of the desire to essentially make things easier. Easier to install, maintain and replace. We also shouldn’t forget the environmental benefits of IOBAC flooring. After all, IOBAC stands for: ‘I owe back to the environment’. For instance, our solutions eliminate the need for adhesives and our flooring can be easily pulled up and relayed elsewhere. If needs be, it can also be recycled. This is a massive plus, especially when you consider that there’s around 400,000 tonnes of waste carpet produced each year in the UK. Over half of this currently goes into landfill.

What is IOBAC all about?

PW: We’re a technology company; a forward-thinking, problem-solving technology company that provides solutions to day-to-day problems. And our technology touches multiple industries – whether it’s with award-winning MagTabs (which are smart little tabs that you can attach to any magnetically receptive floor. Then carpet tiles and plus-four-millimetre vinyl products can be simply connected into place), underfloor heating, heated walls or smart flooring. We’re trying to obliterate the amount of complexity associated with traditional solutions.

IS: Back in 2012, we carried out market research, assessed market trends and what the market’s pain points were. We spoke with retailers, architects, contractors… lots of people! All with the purpose of understanding what a perfect world looked like from a flooring perspective. Armed with that knowledge, we set about delivering on that vision and bringing flooring more up to date with where bricks and mortar retail is going – and where we think it needs to be. We haven’t just innovated for the sake of it. We’ve taken concrete evidence and sound research and turned it into real products that offer real business benefits.

How is IOBAC technology set to impact the future of flooring and heating?

PW: Take our recently developed heated wall technology, which essentially allows you to paint a wall, turn it on via a solar panel and heat your home. Imagine never again needing bulky radiators or storage heaters. Our heat producing paint is integral to the wall. The principles we live by – simplicity, efficiency, sustainability and cost-effectiveness – open up all kinds of opportunities.

Smart flooring, for example, was born out of our magnetic flooring technology. Now we’re producing floors that you can advertise on and floors from which you can harvest data. And because it’s flexible and modular, that data can inform what flooring you lay and where you lay it.

IS: The best example, in my opinion, is our MagTabs solution. We’re creating things that are quick, flexible and easy to install, but also engaging with suppliers to ensure that they don’t have to change their own manufacturing process. You can take standard products off the shelf without having to magnetise them – they can still be used with all of our underlay solutions. We make it easier to engage with our solutions. That’s a big thing and stems from a core business focus of ours: to offer our customers tangible business benefits.

PW: A retailer with a traditional system is a classic example. We’ve worked with M&S and typically, it would take them 24 nights to replace their floor. Imagine the labour cost and lost profits due to downtime. We reduced that by two thirds with an IOBAC system. It took us eight nights. That’s 16 nights that M&S doesn’t have to pay for labour; 16 nights where M&S isn’t losing money, and when M&S looks to replace this flooring in say 10 years’ time, this process is reduced to just four nights. It’ll just require the top surface to be taken up and replaced with a new one. This cuts costs in half. What’s more, our magnetic flooring system isn’t considered a fixed item; it’s removable, which means there are significant tax benefits. And when tiles are damaged – which inevitably they will be, it happens – you only need to replace the one tile and can do so on site. No need for a contractor. It’s a lot easier and a lot quicker.

I’ll also just touch on heated flooring. There are two traditional heated flooring solutions: a heated mat system, which is very thick in terms of install depth and very much adhered to your floor, and pipes, which are very invasive. If there’s a problem with either of these solutions, it’s very difficult to fix. Our solution is modular. You just pop up the top surface, take away the paint and then replace. You can drill into it and remediate very simply. These solutions save time, effort and money; they offer real business benefits for our customers and end-users.

IS: The traditional process of replacing flooring is antiquated. It’s stuck to a sub floor and requires ripping up, which can often damage the sub floor, and it’s contaminated. Those products aren’t recycled, they’re put into skips on site and sent to landfill. Then you have to buy new materials to replace the floor. Our solution can be reused and recycled, and it’s easily uplifted and replaced without affecting the subfloor.

What’s the secret? Where does the magic come from?

PW: Collaboration is key. We’re fortunate enough to collaborate with one of the world’s largest manufacturers of a super conductive additive which forms the super smart, specialist aspect of our heated flooring. We also collaborate to get our patents filed. When it comes to our smart flooring, someone takes the data and provides that data in a report. We then take that and make it real. We’re an asset light company that harnesses expert knowledge as and when we need it. That’s the secret.

IS: Paul’s right. We collaborate with suppliers, partners, specialists etc. But we also collaborate with our clients to improve their processes and make their flooring solutions not only easier for them but work harder for them. Different clients have different needs. For some, acoustics are important. For others, it’s speed of install. What’s important is that we can offer a number of different solutions for a wide range of markets and clients.

PW: We’re also careful to ensure that what we’re doing has a real purpose. We don’t just innovate for the sake of it; we’re a company committed to helping our customers achieve positive results.

IW: Everything we do is done with the end-user and customer in mind which, as Paul says, means that we innovate with real purpose. Our technology may be cutting-edge and complex, but our solutions always remain results-focused, simple and hassle-free.

What’s next?

PW: We have a technology roadmap that builds on our core technologies: superconductive additives, smart capabilities and magnetic technologies. From this foundation, our technologies will expand into other applications and other things we haven’t even thought about yet. And it will all be achieved via collaboration.