One of the key benefits of IOBAC Magnetic Flooring is that it enables a much quicker flooring installation as compared to traditional flooring techniques, which in turn saves money not only in installation project costs, but across the complete life of the floor.

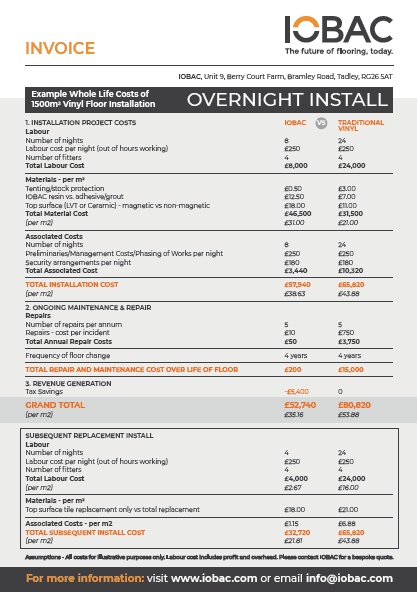

Using figures based on a previous programme working with a major retailer and their supply chain, we took an example project of a 1500m2 vinyl floor replacement completed over a series of nights to minimise disruption to operations and provided a cost breakdown for a IOBAC Magnetic Flooring system versus a traditional vinyl over the life of the new floor.

The results?

Over the life of the floor, the IOBAC Magnetic Flooring system gave a staggering 35% saving (or £33,100) versus the traditional method, calculated as follows:

- Installation Project Costs

Because the process of installing IOBAC Magnetic Flooring has so few steps, it can be installed in a third less time than traditional methods. After the area is cleared, the existing vinyl does not need to be uplifted, simply lightly keyed, and then the IOBAC resin is applied straight over.

The IOBAC Express Cure Resin cures in approximately 1.5 hours, enabling magnetic Luxury Vinyl Tiles to be dry laid on top and immediately trafficked.

Compare this to a traditional process which involves installing tents and stock protection, uplifting the existing vinyl floor and making good the base underneath with preparation materials, all before the new adhesive and Luxury Vinyl Tile can be laid, and the time saving achieved with a IOBAC Magnetic Flooring system is considerable.

8 nights versus 24 nights, to be precise.

This time saving translates into substantial savings in labour and material costs, as well as reduced associated costs such as management and security costs, and a total installation cost of £38.63 per m2 for IOBAC Magnetic Flooring versus £43.88 per m2 for traditional vinyl.

- Ongoing Maintenance and Repair

Rectifying damage is straight forward with IOBAC Magnetic Flooring. Simply lift up the damaged magnetic tile and replace with a new one in a matter of minutes – a quick, easy change that requires no specialised training or contractors and costing £10 for a replacement tile.

Assuming a life of 4 years for the floor and an average of 5 repairs a year, the total repair costs over the life of the floor are then just £200 for IOBAC Magnetic Flooring.

At an estimated £750 per repair for traditional vinyl, total repair costs come to £15,000 across the life of the floor.

- Revenue Generation

An IOBAC Magnetic Flooring installation can actually pay back money. As the magnetic top surface tiles are removable, and not considered to be a permanent part of the structure of the building, then a capital allowance of 24% can be applied, as well as a shorter tax depreciation period.

Plus, because with IOBAC Magnetic Flooring it is so easy to switch individual flooring tiles in and out, retailers have an easy option for additional revenue of selling or renting floor space to brand owners for advertising and promotions

- Replacement

When the time comes for an entire new floor, the replacement process for IOBAC Magnetic Flooring is simple. The IOBAC resin base stays intact so that the top surface tiles just need to be removed and recycled, or stored for future use, before dry-laying new magnetic surface tiles. Switching from one material to another for a completely new look, for example LVT to carpet, is easy.

Again this simplified process saves both time and money versus the traditional process of uplift and preparation of sub-floors before installation.

To conclude, all of the cost savings listed above add up to give a significant project savings when IOBAC Magnetic Flooring is specified for an installation.

Click here to download a full cost breakdown for our example project or contact us to discuss a bespoke cost estimate for your next project using IOBAC Magnetic Flooring.