(Written for Earth Day 2021)

Tackifiers, spray adhesives, contact adhesives …. all methods that have traditionally been used to fix floor coverings to sub-floors over the years.

When architects and designers specify flooring, naturally the flooring material itself takes centre stage in the decision-making. The method by which the flooring is installed is often left to contractors, who may well use those traditional methods.

However, when it comes to adhesive-based installation methods, there are a number of sticky issues (excuse the pun!) that we believe specifiers should be aware of.

But by specifying alternative adhesive-free methods of installation alongside the flooring material, it is possible to save money AND the planet as we detail below.

Environmental Impact

As protecting the Earth’s resources becomes ever more critical, we’d urge specifiers to consider flooring as a circular material – one that can be re-used and re-purposed a number of times before eventually being recycled.

All too often, floor coverings are seen as single-use items, changed because a new design is required, rather than when the flooring wears out.

And when installed using adhesive, this can mean that the materials end up in landfill after just one use. Research by the Changing Markets Foundation concluded that an area the size of Birmingham, UK is thrown away every year in carpet alone.

The Contract Flooring Association (CFA) recently published a comprehensive report “Zero Avoidable Waste in Flooring – Towards a Circular Economy” on opportunities for the flooring industry to manage resources more responsibly.

All major flooring types are covered in the report, with carpet tiles in particular described as

“engineered to perform well in the harshest commercial locations. Often, their design life of 15 years is well in excess of their fashion-led actual life of 7-10 years. This means a second life is well within their asset lifetime.”

Contamination of flooring tile installed using adhesives vs clean tile using IOBAC installation technology

When flooring that has been stuck down with adhesive is uplifted, it’s likely to be contaminated by not only adhesive residue but also the subfloor to which it was adhered, meaning it’s not suitable for recovery or reuse and can’t be recycled.

Even though major flooring manufacturers have long been putting huge amounts of investment into developing products with 100% recyclable fibres and non-PVC materials,

the unfortunate fact is that even 100% recyclable floor coverings cannot be recycled if contaminated with adhesive.

When it comes to waste reduction, we need to be designing and specifying flooring for recyclability and re-use, and considering the flooring material and installation method as a complete system.

Thinking about them in isolation as we have been doing is now proving to be fundamentally “floor-ed”.

Financial Risks

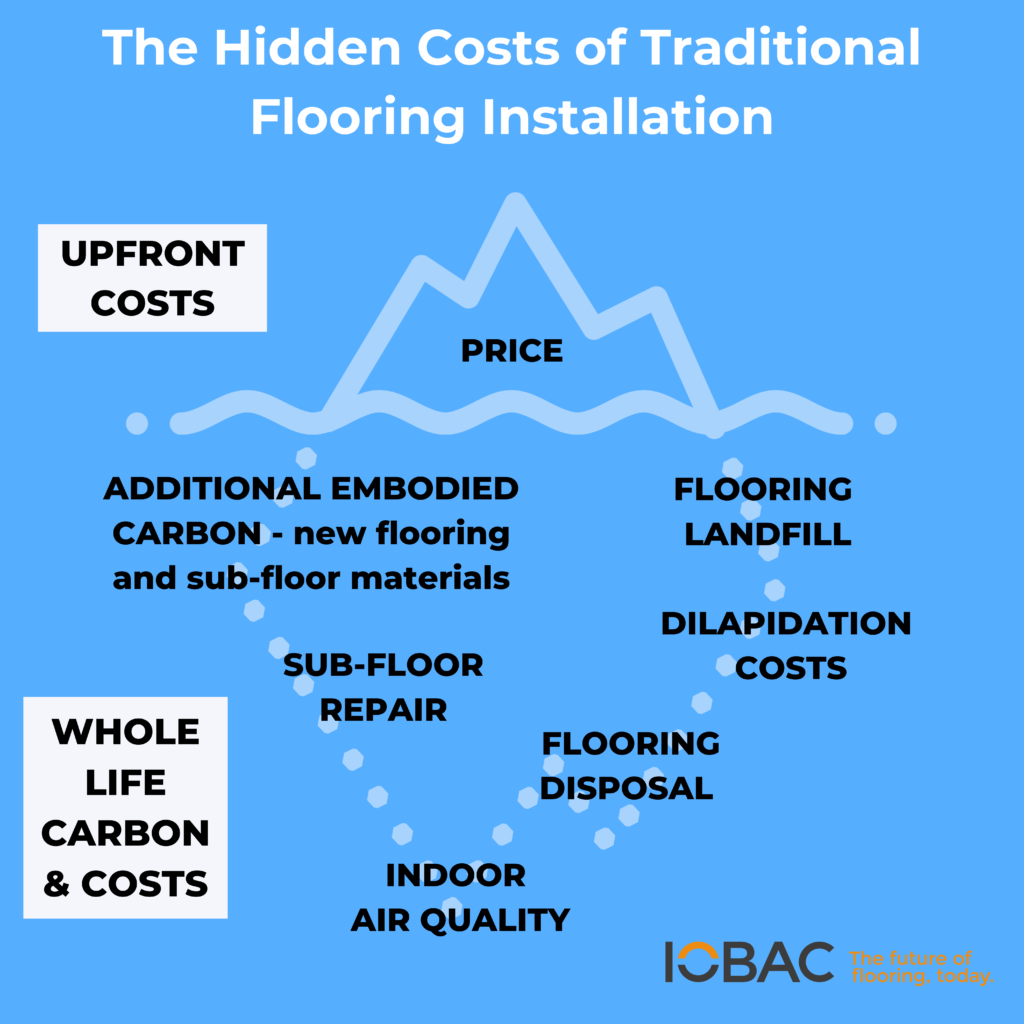

When you start to think about flooring as a circular material, then whole life costs, rather than initial material costs, become the key financial consideration.

Initial installation costs are often lower with adhesive-free methods, as they are quicker and less material-intensive.

And equally, uplifting adhesive-installed flooring after first use can be messy and labour-intensive.

Ceramic tile waste

Think about the effort needed to uplift ceramic flooring, for instance.

Then the sub-floor needs to be made good before the next install can take place. All adhesive contamination and damage to the floor needs to be rectified, adding more time and cost to the process.

Contamination on metal raised access floor

For example, to remove adhesive-residue from a metal raised access floor costs an estimated additional £6.75-9.00 per square metre.

With adhesive-free installation methods, these costs are negligible.

Cleaning off the residue also often requires heavily solvated chemicals which can be problematic in-use.

As the original flooring tiles need to be disposed off, skip hire costs also need to be accounted for – another £0.45 per square metre on average.

Again with adhesive-free methods, the tiles can be repurposed with no need for disposal.

Health Hazards

Some adhesive products carry high levels of Volatile Organic Compounds (VOCs), meaning installers should use Personal Protective Equipment (PPE) to protect themselves from these respiratory hazards.

The associated odour can be very disruptive for all building occupants, both during and for some time after installation.

Tragically there have even been deaths attributed to the use of these products in confined spaces, with some distributors now removing large spray adhesive canisters from sale.

So what is the alternative?

These risks are well recognised, and a number of adhesive-free options have been developed as a result. We cover details of these, as well as case study examples, in our new 30 minute online CPD “A Specifier’s Guide to Adhesive-Free Flooring.”

Our IOBAC adhesive-free flooring installation solution uses Dual-Grip technology which combines magnetism with dry adhesive tack, eliminating the need for any messy tackifiers or wet adhesives, and enabling a clean, odour free process. It’s compatible with a diverse range of floor coverings – LVT, carpet, ceramic, timber, even rubber.

Flooring tiles are held securely in place, hard to shift yet easy to lift for access, repair, maintenance or a more permanent change of design.

Simply pick up the existing tile and replace – there’s no residue or contamination of either the tile or the base. So the base is ready for installation of new tiles straight away, no preparation required, and the flooring that’s been uplifted is perfectly safe and fine to be reused elsewhere or to be recycled.

Taking A Holistic Approach

The installation method of flooring can play a crucial part in the sustainability and economic viability of the overall project, but can sometimes be forgotten from the specification process, resulting in hidden costs and risks.

By specifying adhesive-free installation for their chosen floor covering, whether it’s carpet. LVT or any other material, specifiers can ensure clean accessible floors, with built in redesign, re-use and sustainability credentials.

For more on IOBAC and our approach to sustainability, please visit iobac.com/sustainability

Our free 30 minute narrated CPD “ A Specifier’s Guide to Adhesive-Free Flooring” can be accessed here.