Much has been written about and actioned by the flooring industry to improve the circularity of floor coverings.

In February 2021, the Contract Flooring Association (CFA) published a comprehensive report entitled “Zero Avoidable Waste in Flooring – Towards a Circular Economy” in which it scopes opportunities to build on the good work done so far, namely in:

• Design: The design of the flooring product is key in reducing material consumption, and/or allowing for its re-use and recycling at end of life

• Infrastructure: The collection and processing infrastructure must be further developed to enable practical, cost effective and efficient re-use and recycling routes

• Information: Improving access to information regarding availability of collection systems and which materials and products have been used in a building’s construction would go some way towards diverting material from waste and into re-use or recycling routes

• Business Models: Fundamentally rethinking current business models such as product leasing or a deposit return system to allow manufacturers to retain ownership of their products and facilitate the circular use of material in the manufacture of new products

One of the barriers identified within Design is that

“uplifted material will often have been stuck down which decreases the potential for

re-use and also the recyclability of the product.”

The relatively low recycling rate of resilient flooring is said to be due to constraints in “the ability to collect large quantities from construction and refurbishment projects where the majority of waste arises as well as

contamination from adhesives and levelling compounds still attached to uplifted flooring.”

Compare uplift of a adhesively installed floor plank on left with adhesive free on the right.

To overcome this, the report calls for installation methods that reduce the level of contamination at end of life and allow for easy uplifting.

A holistic approach to flooring

The installation method can have a significant impact on the ease of reuse and recycling of the overall flooring system.

Even a 100% recyclable floor covering can be rendered completely non reusable when installed using less sustainable or adhesive-based methods. Unfortunately, all the hard work and resource that the manufacturer has spent in developing a recyclable product is wasted.

But with the floor covering naturally taking centre stage within the specification process as it plays the major aesthetic part, installation is often forgotten.

The decision as to “what lies beneath” or how flooring is fixed to the sub-floor is often left to contractors further down the line, with major implications for its recyclability on uplift.

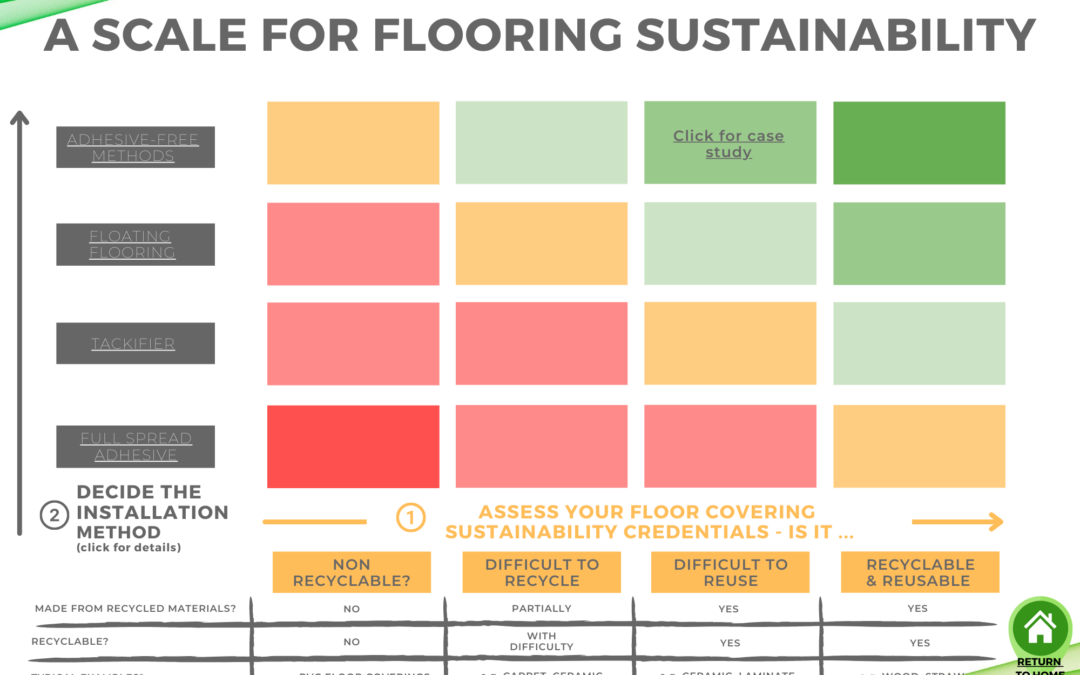

So to help specifiers incorporate reuse at the design phase of projects, at IOBAC we have developed “A Scale for Flooring Sustainability”, available as an interactive pdf.

The scale provides a practical and visual indicator of how to assess and specify flooring systems at the highest levels of circularity by considering the floor covering and its installation method combined.

Using a traffic-light system, the scale clearly shows how the overall sustainability of a floor covering can be improved by changing the installation method.

Our Co-Founder and Director, Ian Spreadborough explains:

“In all the hard work around waste reduction and making flooring a circular material, we urge the industry not to forget about the method of installation.”

“We want to highlight how specifying adhesive-free installation is a straightforward way to help design out waste and encourage material re-use. The message is getting through as we’re seeing a real uplift in architects, designers and clients requesting it as a way of meeting their ESG targets.”

This has been supported by associations such as:

- UK Green Building Council including IOBAC adhesive-free flooring installation solutions in their sustainable Solutions Library

- the BIID recommending the specification of “a glue-less system that allows easy removal and recycling of materials” for carpet tiles in their recently launched Sustainable Specifying Guide

- and RICS SKA rating good practice advocating the re-use or recycling of floor coverings and raised access flooring wherever possible

Saving pounds, as well as the planet

Adhesive-free installation method has financial benefits too:

• labour and material costs significantly reduced during installation

• damaged tiles can be replaced in seconds, reducing ongoing repair and maintenance costs

• no remedial costs for the sub-floor. With adhesive-based methods, the sub-floor (often metal raised access flooring) is also contaminated and has to be made good before the next installation, adding remedial costs for the landlord and tenants.

• no need to purchase new flooring as materials can be reused multiple times

• Tax Benefits – As the flooring tiles are classed as removable, and not considered to be a permanent part of the structure of the building, then an ongoing capital allowance of 19% can be applied

A Vital Chapter

Adhesive-free installation represents a different way to approach flooring – it helps transform it from a single-use material to a flexible design element that can be re-used and re-purposed multiple times before eventually being recycled.

It represents a sustainable choice, with design flexibility and operational cost benefits added in – it is a win-win for all concerned.

Our new Scale for Flooring Sustainability can be found in our Adhesive-Free Flooring Specification Centre, a one-stop shop of online resources including:

• Whitepapers

• a downloadable “Specifier’s Guide to Adhesive-free Flooring” CPD

• Adhesive-free case studies

• Technical product data