Adhesive-Free Flooring

– Saving Time, Money and the Planet in Retail Refurbishment

Having trialled IOBAC flooring installation in the UK, Shell are refurbishing 20 of their forecourt shops across Malaysia using adhesive-free technology.

The video below shows one of the first refits in the programme carried out by experienced petrol station construction contractors, TNO Group of Companies. With the contractor team trained remotely by IOBAC via videoconference, this project is proving to be a great example of fantastic global teamwork with both the client and contractor.

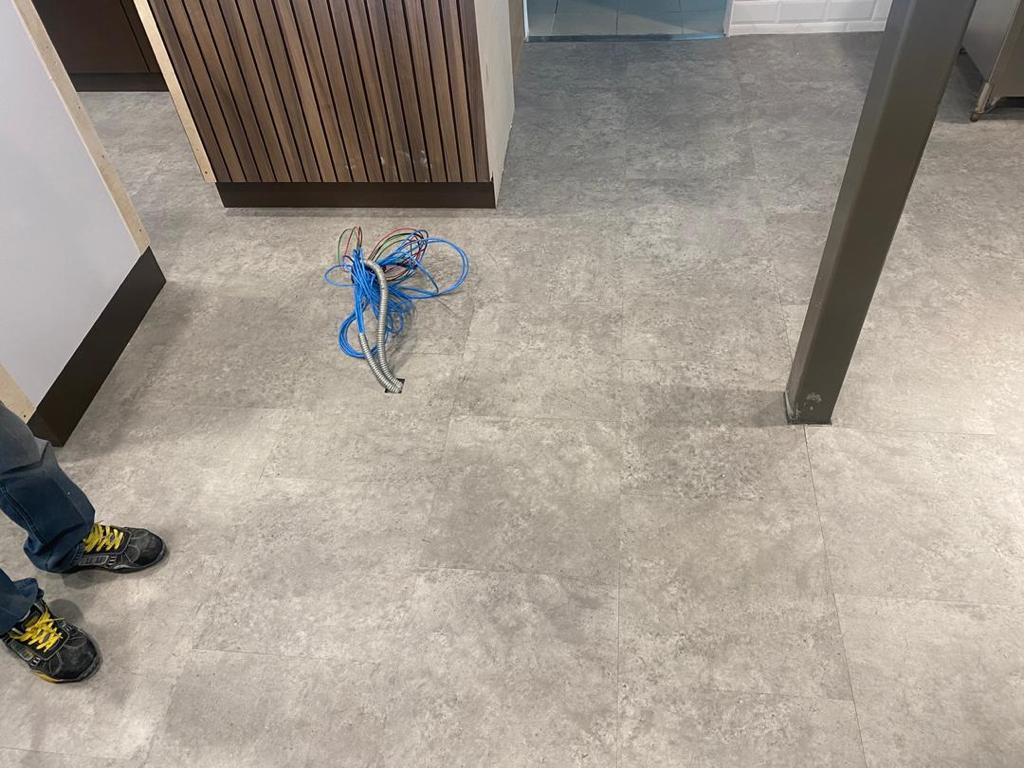

After applying a self-levelling treatment, IOBAC Express Cure resin was laid straight over the existing ceramic tile, with magnetic stone-look Luxury Vinyl Tile dry-laid on top.

Contractor feedback was that the installation was clean, easy and hassle-free compared to conventional methods, with many additional benefits for the client as we detail below.

Video courtesy of TNO Group of Companies

THE BENEFITS

REDUCED INSTALLATION TIME

The project was completed in just 5 days using IOBAC adhesive-free installation technology:

Days 1-2: Self-levelling treatment applied to existing floor

Day 3: Resin application

Days 4-5: Installation of magnetic tiles

Days 1-2: Removal of existing ceramic tiles

Days 3-4: Preparing the sub-floor

Days 5-8: Installation of tiles

This means that with IOBAC, retailers can be up and running in nearly half the time vs traditional methods, minimising disruption and maximising store revenue.

The removal of ceramic tiles is typically carried out using pneumatic tools. This is a noisy, dusty and dirty process, carrying with it respiratory, noise and hand-arm vibration hazards. There is also the risk of electrocution from accidentally digging up underground utilities.

With the IOBAC installation, this removal process is completely eliminated, along with its associated health and safety considerations.

REDUCED WASTE

135m2 of landfill waste due to the removal of existing ceramic tiles was prevented in this project.

They can therefore be easily reused or recycled, rather than having to be disposed of in landfill.

INCREASED FLEXIBILITY

Although the flooring tiles are held securely in place, even in heavy footfall areas, they can be easily uplifted within seconds without the need for specialist contractors or tools.

When re-designing or reformatting areas of the shops, the flooring design can be changed with minimal store disruption

Utilities for the deli area were added in with no problem. The tiles were simply removed, utilities added and the same tiles re-used on top.

Cost Comparisons

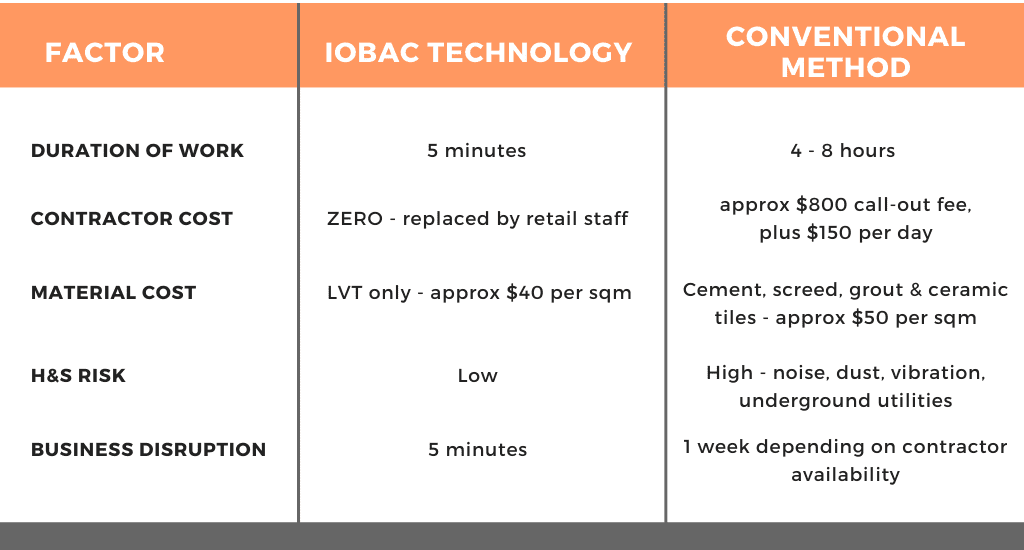

Scenario 1 – Replacement of Damaged Tiles

Any damage to the floor needs to be repaired quickly, efficiently and cost-effectively. Scuffs, marks and dents can not only damage brand reputation, but could also cause trip hazards. Repairs need to be carried out with minimal store downtime and risk.

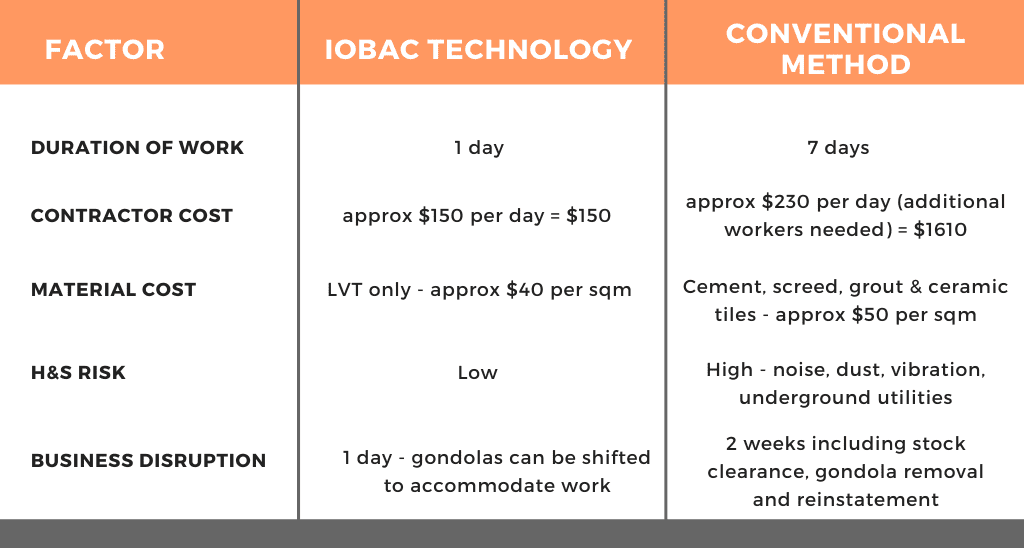

Scenario 2 – New Design

Sometimes a complete replacement of the floor will be required, for example for a new brand design.

As flooring installed using IOBAC adhesive-free installation technology can be easily uplifted, there is no need for the store to be completely cleared of stock and display equipment. Contractors can simply work in small areas, moving gondolas around accordingly. Work is completed in just one day vs a week.

Scenario 3 – Store Closure

If the decision is made to close a store, then with IOBAC, there is minimal wastage of materials, impact on the environment and CapEx charges.

The Luxury Vinyl Tile can be reused, whereas conventionally all materials from ceramic tiles to screed would go to landfill.